Efficient label printing

In many areas, nothing would work without them: labels and the associated label printers. Whether at the point of sale or in logistics in the broader sense – labels ensure that goods find the right way to warehouses or anywhere to customers. To ensure that label printing works properly and smoothly, one should know about the special features of label printing. Read on to learn what advantages ThinPrint offers for label printing.

The Printing Technologies Used in Label Printing

Usually, none of the typical office printers are used for label creation. Instead, they are usually thermal printers and specifically are direct thermal printers or thermal transfer printers. With direct thermal printers, the label writing is virtually burned onto a temperature-sensitive paper, whereas a thermal transfer printer uses a coated film with a temperature-sensitive coating in which heat dissolves the coating from the foil to transfer it to the paper. Laser printers are also used for label printing, as are matrix printers, which use needles to form letters and numbers.

From ThinPrint’s perspective, it doesn’t matter which printer a company chooses for label printing purposes as a label is at its core a printout of a document. For this purpose, the data must be transferred from the system to the intended label printer. In order to be able to take the special features of the label printers into account, you need the native printer drivers in the system, i.e. the drivers that the manufacturer has provided for these printers.

Paper for Label Printing

When printing labels standard paper formats such as DIN A4 or Letter are not normally used. Each printer model has its own formats, and not every printer supports every format. In addition, individual formats can also be defined as different service providers, such as in logistics, have their own format. A common special format is that of DHL labels, to name an example. Additionally, point-of-sales printers often work with continuous paper and printing continues until all the data has arrived at the printer and has been processed. Such is reflected in the paper selection offers as the paper that matches the printers is then available as normal or thermal paper, self-adhesive, non-adhesive, or in various formats such as continuous paper.

The Connection in Label Printing

Another important aspect of label printing is the connection between the generation of the document and the printer and vice versa. Are the printers connected serially or via USB interface? Cheaper models usually contain a USB port. A WLAN connection is also often available, and if the print output is particularly business-critical, such as printing boarding passes at the airport, then the printers are usually connected via a network cable.

All in all, label printing is often business-critical. If printing is not possible in logistics, at the airport, or in hospitals, then the business comes to a virtual standstill. On the other hand, if someone in the office can’t print out their draft document immediately, the company doesn’t come to a halt, yet a malfunctioning print output is frustrating for those involved and reduces effectiveness of processes.

The Right Printing Solution for Label Printing

There are a number of printing solutions on the market that use the PDF format in printing logistics and these solutions cannot fully support label printers for technological reasons. Thus, special setting options for the printout are usually not available. ThinPrint, a print management system that has been continually developed and optimized over decades, supports label printing in all its facets. ThinPrint has numerous functions that enable label printing with all its special settings, regardless of location and with little administrative effort.

ThinPrint Output Gateway Printer Driver

An interesting component of the ThinPrint solution for organizations is the ThinPrint Output Gateway for driver-free printing. The Output Gateway can simulate printers and printer-specific settings can be adopted. An important advantage here is that users only need to find their way around a standardized print interface, which is advantageous if someone uses many different printers. A huge plus for IT administration: When using the ThinPrint Output Gateway, no printer drivers need to be installed and managed on users’ virtual or physical desktops.

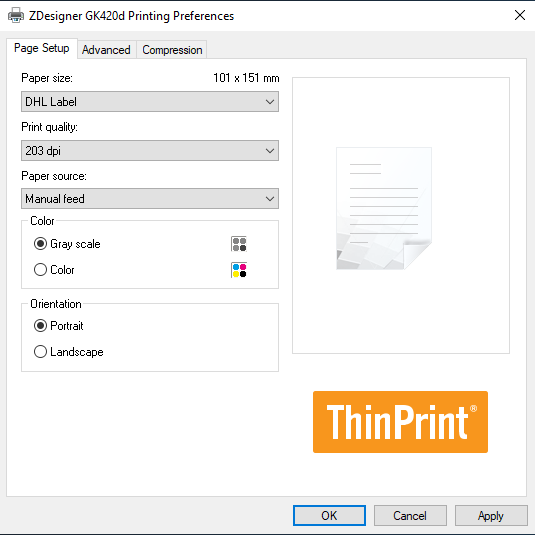

In conjunction with ThinPrint V-Layer technology, the native drivers on the ThinPrint server are virtually hidden behind the virtual Output Gateway driver. Nevertheless, users can select important settings when printing labels because the V-Layer takes over the setting options of the native driver for the Output Gateway. Supported printing options include paper size (e.g. 102mmx50mm), layout (i.e. portrait or landscape), and resolution (e.g. 100 or 300 dpi).

In the instance that additional specific printer settings of individual label printers have to be configured, such as the burn-in time on the thermal paper, an IT administrator can preset this permanently on the ThinPrint server. If a user wants to change settings during printing, ThinPrint also allows native drivers to be used on the virtual or physical desktop. In this regard, a company benefits from a wide range of useful ThinPrint features, such as automatic provisioning of the right printers, high availability, print data encryption, data compression, and an overall reduction in administrative effort.

Always the Right Printer

ThinPrints AutoConnect ensures that all users always have access to the right printers, which is particularly practical when employees are on the move within the company and use different printers. This is a common scenario in hospitals and logistics as nursing staff and warehouse staff are frequently on the move in different parts of the building, and ThinPrint ensures that the right printers are available on site for such individuals. Users can also take advantage of the User Self Service, which allows them to select and map their own printer.

Simple Connection of Remote Offices

With the ThinPrint print appliance ThinPrint Hub, the printing infrastructure of remote locations, such as warehouses, can easily be integrated without IT knowledge. All print jobs are securely encrypted during transmission and in areas with narrowband connections, ThinPrint efficiently compresses print data.

High Availability

ThinPrint ensures high availability of the print function with a sophisticated system consisting of, among other things, load balancing, automatic early detection of faulty spool processes, and an early warning system for print servers. This is particularly important for label printing, which is often business-critical.

Overall, it can be said that the special challenges of label printing lie primarily in the large number of special printer settings. Compounding this is the need for printing to actually work all the time. Without the output of the labels, operations in many companies would come to a standstill and can cause significant damage.

With ThinPrint’s technologies for low administration support of native printer drivers and for ensuring highly available print output, companies are on the safe side when it comes to label printing. Print output is reliable, always in the right place, secure and true to format, and requires little administration.

Get started with label printing!

Download ThinPrint Engine and discover efficient label printing. The first 30 days are completely free, including all ThinPrint features.